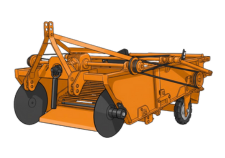

The BAMPLM 01 is engineered with features and specifications that meet the demands of mulching-based cultivation under Indian agrarian conditions:

Key Features:

- Robust, heavy-duty frame with adjustable bed levelling and depth control — provides precise film laying even on uneven soil.

- Adjustable film-tension rollers and side-sealing wheels — ensure tight, wrinkle-free laying of plastic mulch.

- Quick-adjust linkage mount compatible with 3-point tractors (20–35 HP) — easy and fast attachment/detachment.

- Film feeding tray with adjustable width — accommodates different plastic film widths (e.g. 0.8 m, 1.0 m, 1.2 m).

- Depth-control wheels for bed preparation and seedbed leveling — ensures smooth soil surface before film lay.

- Bolt-mounted rollers and wheels — for easy replacement and maintenance.

- Protective frame guards — to prevent soil splash and protect rollers during operation.

- Low-maintenance roller bearings and sealed axle — reducing long-term maintenance requirements.

Model Summary:

The BAMPLM 01 is optimized for 20–35 HP tractors — a segment common among small to medium Indian farms. Its working width is ideal for vegetable beds, cash crops, and drip-irrigated plantations. The sturdy construction, adjustable film-tension mechanism, and easy-to-use linkage make it an excellent choice for farms that practise seasonal mulching and wish to minimize labour and time for bed preparation and mulch laying.

Detailed Specifications of BAMPLM 01 Mulching Paper Laying Machine

|

Parameter

|

Specification

|

|

Working / Film Laying Width

|

~1000 mm (approx. 1 meter) — suitable for standard mulch film rolls

|

|

Suitable Tractor HP

|

20 – 35 HP

|

|

Drive Type / Mounting

|

Tractor 3-point linkage, direct PTO/ground-wheel driven film feed (optional)

|

|

Film Roll Width Compatibility

|

0.8 m / 1.0 m / 1.2 m (adjustable tray)

|

|

Sealing / Tension Mechanism

|

Adjustable tension rollers + side sealing wheels for firm film placement

|

|

Bed Preparation Wheels

|

Included — two rear depth-control wheels for leveling soil before film lay

|

|

Machine Weight (approx.)

|

~180 kg (excluding film roll)

|

|

Linkage Type

|

Standard 3-point CAT I/II linkage — for easy attachment

|

|

Roller & Wheel Mounting

|

Bolt-mounted — for easy replacement/maintenance

|

|

Additional Design Features

|

Adjustable frame height, protective side guards, film-tray with tightening springs, sealed bearings on rollers, quick-detach linkage pins

|

These specifications make BAMPLM 01 a user-friendly and reliable implement for mulching plastic laying — delivering both effectiveness and ease of use.

BAMPLM 01 Mulching Paper Laying Machine – Price in India

The BAMPLM 01 Mulching Paper Laying Machine typically comes within the price range of approximately ₹ 90,000 – ₹ 1,35,000, depending on region, dealer stock, and optional attachments (e.g. adjustable tray, extra depth wheels, sealing wheels).

Given the labour savings, time efficiency, and long service life, this represents a compelling value — especially for small to mid-size farmers or farms doing seasonal vegetable, horticulture or cash-crop cultivation requiring mulching operations.

Why Choose [Your Farm Equipment Dealer / Supplier] for BAMPLM 01 Mulching Machine?

We make it easier for farmers to find the right farm machinery with complete confidence and convenience. Our dedicated section for BAMPLM 01 Mulching Paper Laying Machine helps you explore detailed specifications, features, images, and price information all in one place — ensuring a smooth buying experience. Whether you are a smallholder farmer, vegetable grower, or contractor, we help you choose the right mulching implement suited to your land, crop type, and tractor capacity.

We also provide smart tools like price filters, HP filters, comparison options, and expert guidance — so you can shortlist the machine that fits your budget and farming needs without wasting time. On top of that, we offer transparent pricing, trusted dealer connections, and genuine product listings — giving you peace of mind with every purchase.

So, if you are looking to buy the BAMPLM 01 at the best price with reliable information and support, visit our page and choose the perfect mulching paper laying machine to enhance your farming efficiency.

Popular Mulching Machines & Alternatives (Including BAMPLM 01)

Explore some commonly used mulch-film laying machines and related implements. These are widely preferred by Indian farmers for vegetables, horticulture, drip-irrigation beds, and other mulched cropping systems — trusted for efficiency, reliability, and value.

|

Model Name / Type

|

Key Features

|

Suitable For / Best Use

|

|

BAMPLM 01 Mulching Paper Laying Machine

|

Adjustable film-tension rollers, 1 m working width, bolt-mounted rollers, 20–35 HP tractors

|

Vegetable beds, horticulture, drip-irrigation, small/medium farms

|

|

Basic Mulch-Laying Trailer (Single-Row)

|

Simple ground-wheel-driven film feeder, narrow width

|

Small plots, greenhouse beds, narrow vegetable rows

|

|

Multi-Row Mulch-Laying Seeder-Mulcher

|

Combined seeding + film laying + fertilizer dropper

|

Larger farms, vegetable or cash crops, mechanized planting + mulching

|

|

Hand-Operated Mulch Lay Roller

|

Manual push-type film laying roller

|

Very small plots, or areas inaccessible to tractor

|

|

Mulch Laying + Drip Irrigation Deployer

|

Film laying + drip-tape embedding attachment

|

Vegetable & cash-crop beds needing irrigation + mulching

|

Note: The above list represents commonly preferred mulch-laying options. Actual availability, features, and model names may vary depending on your location, dealer stock, and season. Always verify specifications (film width compatibility, tractor HP suitability, frame design) before purchase.

Benefits – What Makes BAMPLM 01 Stand Out

- Efficient, Uniform Mulch Film Laying

Thanks to its film-tension rollers, side-sealing wheels, and adjustable tray for different film widths, BAMPLM 01 lays plastic mulch smoothly and tightly. This reduces wrinkles and air pockets — ensuring better soil-film contact, consistent moisture retention, and improved effectiveness of plastic mulch for weed control, moisture conservation, and temperature regulation.

- Time, Labour, and Cost Savings

Manual film laying is labour-intensive and time-consuming, especially for several beds or large vegetable plots. Mechanizing the process with BAMPLM 01 significantly reduces labour effort and speeds up mulching — often completing in hours what manual work might take days. For small to medium farms managing multiple beds, this translates to substantial time and labour savings.

- Compatibility & Flexibility with Common Tractors

The machine is designed for 20–35 HP tractors — a common segment among small to medium farms across India. Its standard 3-point linkage and straightforward film-feeding mechanism mean it can be easily attached to existing tractors with minimal modification. As a result, most farmers can adopt mulching with existing tractors, without needing specialized equipment.

- Durability & Low Maintenance

Built with a heavy-duty frame, bolt-mounted rollers, sealed bearings, and adjustable attachments, BAMPLM 01 is sturdy yet simple to maintain. Its design avoids complex hydraulics or electrics, reducing points of failure. Easy access to rollers and sealing wheels makes maintenance, replacement, or adjustment straightforward — helping keep long-term operating costs low.

- Versatility — Across Crops & Bed Types

While optimized for plastic mulch film laying on vegetable beds and horticulture crops, the machine’s adjustable width and roller setup make it adaptable for different bed spacing, film widths, and film types (black, clear, biodegradable). This makes it a versatile investment for farms growing multiple crops, changing film width seasonally, or switching between different cropping patterns.

Use Cases – Who Should Use BAMPLM 01 Mulching Machine

The BAMPLM 01 Mulching Paper Laying Machine is especially well-suited for:

- Farmers cultivating vegetables, horticultural crops, or cash crops on small to medium plots (say 0.5 – 5+ acres), where manual mulch laying is laborious and time-consuming.

- Farms aiming to adopt plastic mulching to improve yields, reduce weeds, conserve soil moisture, and manage soil temperature.

- Farms using 20–35 HP tractors — a common tractor class for small and marginal farmers — who want a plug-and-play mulch-laying implement compatible with existing equipment.

- Farmers practicing crop rotations, or switching between different crops/bed sizes — the adjustable film-tray makes it easy to adapt for different seasons or crops.

- Agricultural contractors or service providers offering bed-prep + mulch-laying services to multiple small farms — the machine’s efficiency and speed make it a good tool for hired operations.

Operating Considerations & Best Practices

To get the best performance and longevity from your BAMPLM 01 — and ensure safe, effective use — here are some recommended practices:

- Tractor Compatibility: Ensure your tractor lies within the 20–35 HP range as per spec. Over- or under-powered tractors may reduce film-laying quality or strain the implement.

- Proper Linkage & Film Setup: Use the standard 3-point linkage with correct pins, and ensure the film roll is properly mounted and centered on the feeding tray before operation. Check the tension rollers and side sealing wheels are adjusted correctly for the width of film being used.

- Field Preparation: Before laying mulch film, prepare your beds properly — level the soil, remove stones or debris, and ensure a smooth bed surface. This prevents film tears or uneven placement.

- Operate at Appropriate Speed: Use moderate tractor speed — too fast can cause film wrinkles or tearing; too slow may cause uneven film lay or soil drag.

- Roller & Sealing Wheel Maintenance: After every few uses (especially on dusty or sandy soil), clean rollers, sealing wheels, and bearings; check for wear; re-grease bearings as needed.

- Check for Debris and Stones: Stones or debris may damage the film or rollers — remove them before operation.

- Protect Film During Loading: While loading film rolls, ensure film edges are not torn, and tray springs or clamps are properly tightened to hold the roll securely.

- Storage: After use, clean soil/clay off the machine, dry if possible, and store in a covered shed to avoid rust or deterioration of rollers and frame.

Comparing BAMPLM 01 with Alternative Mulching Methods & Implements

Manual Mulch Laying vs. BAMPLM 01

Manual laying of mulch film is labour-intensive, slow and often results in uneven film lay, wrinkles, air pockets — reducing mulch effectiveness. In contrast, BAMPLM 01 uses rollers and sealing wheels to lay film uniformly, tightly and quickly — saving labour and ensuring better mulch performance.

BAMPLM 01 vs. Basic Ground-Wheel Film Feeders

Basic ground-wheel feeders may be cheaper but often lack precise tension, sealing, or film-width adjustment — leading to loose mulch, poor soil contact, or film damage. BAMPLM 01, with adjustable tension rollers, bolt-mounted parts, and better frame stability, delivers more reliable film-laying across different conditions.

BAMPLM 01 vs. Multi-Row Mulch Seeding Machines

While multi-row machines combine seeding + mulching + fertilizer drop, they are often more expensive and complex, and may require higher HP tractors or maintenance. BAMPLM 01 offers a simpler, cost-effective solution for farms that only need mulch film laying — suitable for small/medium operations or starter mulching setups.

Real-World Benefits for Farmers

Based on typical usage and the design advantages, here’s what farmers using BAMPLM 01 can expect:

- Significant reduction in time and labour for mulching: large vegetable beds or multiple plots that earlier took days to mulch manually can be prepared in hours — enabling timely bed-prep and planting.

- Lower dependency on seasonal labourers: reduces need for manual labourers for film-laying, especially beneficial where labour is scarce or costly.

- Improved crop establishment and yield potential: uniformly laid mulch ensures better moisture retention, weed control, soil temperature regulation — resulting in healthier plant growth, improved germination or transplant establishment, and potentially higher yields.

- Reduced long-term operational cost: durable build, low-maintenance rollers, and a simple mechanical design lead to lower maintenance costs and long service life — improving cost-to-benefit ratio over seasons.

- Flexibility and versatility: though optimized for plastic mulch laying, the adjustable film tray and tension rollers make it suitable for different film widths and crops — giving farmers flexibility across cropping seasons.

- Better farm management and scheduling: mechanical mulching helps farmers complete bed preparation and mulch-laying quickly, enabling timely planting or transplanting — important for season-critical crops in vegetable and horticulture farming.

Potential Limitations & Things to Watch Out For

No implement is perfect for every situation. While BAMPLM 01 offers many advantages, farmers should be aware of potential limitations:

- Tractor HP Limitation: The implement is designed for 20–35 HP tractors. If you have a much lower HP tractor — say <20 HP — performance may degrade; if higher HP tractor, you may not be utilizing full available power but it's fine.

- Soil Conditions: Very stony or rocky fields may damage film-laying rollers or tear mulch film. Proper removal of stones is advised before operation.

- Need for Maintenance: Rollers, bearings, sealing wheels and film-tray clamps need regular inspection, cleaning, and maintenance. Neglecting these may lead to poor film-laying quality or breakdown.

- Initial Investment Cost: For very small plots or hobby gardens, the cost (₹ 90,000–₹ 1,35,000) may be high relative to land size or yield value. Return on investment may take longer.

- Skill & Adjustment Requirements: Operators must learn to adjust roller tension, film width settings, and tractor speed correctly. Improper adjustment may lead to poor film lay or film damage.

- Not Suitable for Unprepared Soil: If soil is uneven, full of debris, or not leveled, mulch film may not lay properly. Bed preparation (leveling, stone removal) is essential before using the machine.

Guidance: Is BAMPLM 01 Right for Your Farm?

If you are a farmer in India and meet the following criteria, the BAMPLM 01 Mulching Paper Laying Machine is a good investment:

- You have or plan to use a 20–35 HP tractor.

- You cultivate vegetables, horticulture crops, or cash crops over moderate to small-to-medium area (say 0.5 acre to several acres) and want efficient bed preparation and mulching.

- You value labour savings, time efficiency, and mechanized operations — especially where manual labour is costly or hard to source.

- You have fields where soil is reasonably free from stones and debris, and can be leveled before film laying.

- You intend to maintain the implement properly (rollers, seals, bearings, clamps) to ensure long life.

- You might use the implement for different crops or seasons, possibly switching film widths — maximizing its utility beyond a single crop.

On the other hand, if your farm is very small (say few beds), or your tractor is underpowered (<20 HP), or your soils are very stony/uneven — you might consider simpler manual methods, ground-wheel film feeders, or wait until you scale up before investing.

Practical Tips for On-Field Use of BAMPLM 01

- Pre-check linkage & film roll loading: Before hooking up the machine, inspect the 3-point linkage setup and ensure the film roll is properly secured in the feeding tray. Adjust tension rollers and side-sealing wheels according to film width.

- Bed Preparation: Level the soil, remove stones and debris, and ensure a smooth seedbed before laying the film. A well-prepared bed is critical for clean film laying and avoiding tears.

- Operate at Optimal Speed: Use moderate tractor speed — avoid going too fast, which may stretch or tear the film; too slow may cause soil drag or uneven film feed.

- Roller & Sealing Wheel Maintenance: After every few uses — particularly in sandy or dusty soil — clean rollers and sealing wheels, check for wear or damage, re-grease bearings, and tighten bolts as needed.

- Film Handling: While loading and unloading film rolls, handle carefully to avoid edge tears. Ensure the tray springs or clamps are properly tightened to hold the roll firmly.

- Storage After Use: Clean off soil or dust, ensure rollers are free of debris and moisture; store the machine in a covered shed to prevent rust or deterioration of rollers, bearings, or frame.

- Periodic Inspection: Before each mulching season, check all rollers, bearings, seals, and wheel bolts — especially after prolonged storage or heavy-use seasons — to avoid operational failure.

Conclusion: Overall Value & Recommendation

The BAMPLM 01 Mulching Paper Laying Machine is a thoughtfully designed, user-friendly implement that combines efficiency, durability, and practicality. It stands out for mulching operations owing to its adjustable film-tension rollers, wide working width, heavy-duty yet simple frame, and bed-preparation attachments — all aimed at ensuring precise, uniform, and speed-optimized mulch film laying.

For small to medium farms cultivating vegetables, horticulture or cash crops — and for farmers using 20–35 HP tractors — this machine represents a strong value-for-money investment. Its benefits in labour savings, time efficiency, and improved mulching effectiveness — along with low maintenance and long service life — make it a great tool to modernize bed preparation and crop management.

At the same time, with proper use, maintenance, and good field preparation, it can serve as a versatile implement over multiple cropping seasons and for different crop types — giving long-term utility beyond just a single season or crop.

Therefore, if your farm operations match the described criteria — tractor HP, field size, desire for mechanized mulching, and willingness to maintain the implement — adding the BAMPLM 01 Mulching Paper Laying Machine is a wise decision. It helps modernize mulching operations, reduces manual effort, and positions your farm for better efficiency, productivity, and crop performance.

✔ Pros

✔ Pros  ✘ Cons

✘ Cons