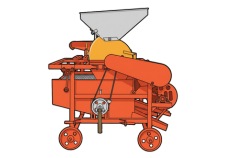

The Bull Telescopic Unloader is designed with features that meet the demands of Indian farms and storage operations for bulk grain handling. According to the manufacturer’s specifications:

Key Features:

- Heavy-duty telescopic boom adjustable from 6 to 12 meters (approx.) for versatile unloading.

- High-capacity belt conveyor with anti-slip surface for smooth grain transfer.

- Hydraulic lift and extension system for effortless height and reach adjustment.

- Sturdy steel frame with reinforced joints for stability during operation.

- Side guard rails and safety covers for operator protection.

- Durable wheels for mobility in farmyards, silos, and storage depots.

- Low power requirement and efficient fuel/electric consumption.

- Easy maintenance with accessible lubrication points and replaceable conveyor components.

Model Summary

The Bull Telescopic Unloader is optimized for medium to large farms, warehouses, and agro-processing units. Its telescopic boom allows unloading at variable heights and distances, while the robust conveyor and hydraulic system enable smooth, fast, and safe grain transfer. The durable steel frame, protective covers, and high-quality components ensure long-term service life, even under continuous heavy usage.

Detailed Specifications of Bull Telescopic Unloader

|

Parameter

|

Specification

|

|

Boom Length

|

6–12 meters (telescopic adjustable)

|

|

Conveyor Belt Width

|

600 mm

|

|

Conveyor Belt Type

|

Heavy-duty rubber with anti-slip surface

|

|

Power Requirement

|

25–35 HP tractor PTO or electric motor option

|

|

Hydraulic Lift System

|

Single/dual-acting hydraulic cylinder for extension & height adjustment

|

|

Maximum Grain Transfer Capacity

|

15–20 tons/hour (depending on material)

|

|

Machine Weight

|

980 kg approx.

|

|

Mobility

|

Heavy-duty wheels with brakes

|

|

Frame Material

|

High-grade steel with reinforced joints

|

|

Additional Design Features

|

Safety covers, side guard rails, free maintenance tools, easy access lubrication points

|

Bull Telescopic Unloader – Price in India

As per recent listings and authorized dealers, the Bull Telescopic Unloader typically falls within the price range of ₹5.50–6.50 Lakh. Some sources indicate a starting price around ₹5,75,000 for the standard 6–12 meter model. Considering operational efficiency, labour savings, reduced unloading time, and durability, this represents strong value for medium to large-scale farms and agro-processing units.

Why Choose Tractor For Everyone for the Bull Telescopic Unloader?

At Tractor For Everyone, we make it simple for farmers and agro-operators to find the right machinery with confidence. Our dedicated section for the Bull Telescopic Unloader provides complete specifications, images, and price information in one place.

We also offer tools such as price filters, power compatibility options, model comparisons, and expert guidance — helping you shortlist the unloader that suits your farm or storage needs. Transparent pricing, verified dealer connections, and authentic product listings ensure peace of mind during your purchase.

Popular Bull Telescopic Unloader Models

|

Model Name

|

Key Features

|

Suitable For / Best Use

|

|

Bull 6–12m Telescopic Unloader

|

Adjustable telescopic boom, hydraulic lift, 600 mm belt

|

Unloading grains from medium to large trucks, storage bins

|

|

Bull 8–14m Heavy-Duty Unloader

|

Extended reach, reinforced frame, high-capacity belt

|

Large farms, grain silos, warehouses

|

|

Bull 6m Compact Unloader

|

Lightweight, easy mobility, basic conveyor

|

Small storage yards, small farms

|

|

Bull 10m Multi-Purpose Unloader

|

Hydraulic tilt, extended conveyor, versatile operation

|

Agro-processing units, multi-crop handling

|

Note: Availability may vary depending on dealer, season, or location. Always verify specifications, belt width, and hydraulic requirements before purchase.

Benefits – What Makes Bull Telescopic Unloader Stand Out

- High-Efficiency Grain Transfer

The telescopic boom and powerful conveyor allow fast unloading, reducing operational time. Adjustable length ensures reach to high truck beds or storage bins, minimizing manual labour.

- Labour & Time Savings

Mechanized unloading reduces dependence on manual labour and speeds up harvest handling. Farms or warehouses can handle larger volumes efficiently.

- Compatibility & Flexibility

Compatible with 25–35 HP tractor PTO or electric motor setups, making it adaptable for different farm machinery configurations.

- Durability & Low Maintenance

Heavy-duty steel frame, reinforced joints, high-quality belt, and accessible lubrication points ensure long-term performance with minimal maintenance.

- Versatility Beyond Grain Unloading

Can also transfer pulses, oilseeds, or other bulk materials; suitable for farms, warehouses, and agro-processing units.

Use Cases – Who Should Use Bull Telescopic Unloader

- Medium to large-scale farmers harvesting grains or pulses in bulk.

- Agro-processing units, warehouses, and silos requiring fast unloading.

- Operators looking to reduce manual labour and increase productivity.

- Farms with tractors in the 25–35 HP range needing a plug-and-play unloading solution.

- Contractors providing material handling services to multiple farms.

Operating Considerations & Best Practices

- Power Compatibility: Ensure tractor or motor meets recommended HP for smooth operation.

- Field & Storage Prep: Avoid excessive grain spillage; position machine on stable ground.

- Hydraulic Safety: Regularly inspect hydraulic hoses, cylinders, and connections.

- Belt Maintenance: Check belt alignment, tension, and clean any debris after use.

- Operator Safety: Keep clear of moving conveyor, ensure all guards are in place, and never operate with people nearby.

- Storage: Retract boom and store in sheltered area when not in use to prevent rust.

Comparing Bull Telescopic Unloader with Alternative Grain Handling Methods

- Manual unloading vs. Telescopic Unloader: Manual unloading is labour-intensive and slower, especially for large trucks. The unloader significantly cuts time and reduces human effort.

- Stationary conveyor vs. Telescopic Unloader: Stationary conveyors require moving trucks to the conveyor, while telescopic models can extend to reach trucks or bins directly, offering flexibility.

- Other Telescopic Unloaders: Smaller models have limited reach and capacity; larger models may require higher HP tractors and may be less maneuverable. The Bull Telescopic Unloader balances reach, capacity, and compatibility for 25–35 HP tractors.

Real-World Benefits: What Farmers Gain

- Faster unloading of trucks and storage bins.

- Reduced manual labour and associated costs.

- Smooth and consistent material transfer reduces spillage and waste.

- Versatility for multiple crops and materials.

- Durable construction ensures long-term utility across seasons.

Potential Limitations & Things to Watch Out For

- Requires 25–35 HP tractor or equivalent power source.

- Not ideal for sticky or fine powders that can clog the belt.

- Needs regular belt alignment and hydraulic maintenance.

- Bulky footprint may limit use in narrow storage areas.

- Overloading can cause premature wear or damage.

Guidance: Is Bull Telescopic Unloader Right for Your Farm?

Suitable if you:

- Have a 25–35 HP tractor or compatible electric power source.

- Handle grains or pulses in medium to large volumes.

- Want to save labour and unloading time.

- Operate in fields, warehouses, or silos requiring reach flexibility.

May reconsider if:

- Farm or storage area is very small.

- Tractor power is below recommended HP.

- Handling sticky or fine powdered materials.

Practical Tips for Use (On-field & Storage)

- Pre-check tractor/motor connection and hydraulic setup.

- Position machine on stable, level ground.

- Adjust boom length for optimal unloading distance.

- Regularly clean and inspect conveyor belt, hydraulic hoses, and lubricate moving parts.

- Store retracted, covered, and protected from rain or dust when not in use.

Conclusion: Overall Value & Recommendation

The Bull Telescopic Unloader is a robust, high-capacity, and farmer-friendly grain handling implement. Its telescopic boom, hydraulic lift system, heavy-duty conveyor, and durable construction make it an ideal solution for medium to large farms, warehouses, and agro-processing units.

For operators with compatible power sources, it offers time savings, labour reduction, better material handling, and long-term durability. With proper maintenance, it serves as a versatile investment for multiple crops and farm operations — making it a strong value-for-money choice for modern agricultural efficiency.

.jpg)

✔ Pros

✔ Pros  ✘ Cons

✘ Cons