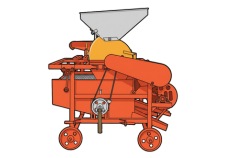

The Bull Radial Unloader is engineered with advanced features and structural components that meet the demanding requirements of modern grain handling, warehouse operations, and large-scale agricultural unloading. According to the manufacturer’s specifications and product design philosophy, the unloader is developed to deliver maximum stability, consistent discharge, and long service life, even under continuous heavy-duty usage.

This machine is built to simplify and accelerate bulk unloading processes, enabling operators to unload grain trolleys, trailers, carts, or bulk storage with minimal manual involvement. Its radial design allows for evenly spreading materials across a selected radius, ensuring uniform distribution and reducing labour-intensive levelling tasks.

The Bull Radial Unloader’s combination of heavy-duty build quality, efficient rotational control, and user-friendly setup makes it one of the most reliable radial unloaders in its category — well suited for commercial farms, grain procurement centers, co-operative societies, large warehouses, and rural mandi operations.

Key Features

High-Efficiency Radial Discharge System

The signature feature of the Bull Radial Unloader is its radial discharge arm, which spreads bulk material in a uniform pattern across a wide radius. This mechanism reduces the need for repeated repositioning and manual levelling.

Heavy-Duty Steel Construction

Built with high-tensile steel, reinforced joints, and a robust support frame, the machine withstands long-hour operations, high-volume loads, and continuous rotational movement.

Strong PTO-Driven System

Designed to operate via tractor PTO, the machine ensures consistent power transfer and smooth unloading. Certain models may support hydraulic rotation depending on configuration.

Balanced Rotor & Flow-Controlled Outlet

Ensures smooth and uniform discharge without clogging, vibration spikes, or material surges — crucial for crops like wheat, maize, soybeans, and millets.

Wide Rotation Angle (180°–360°)

Depending on model, the machine supports controlled radial coverage, allowing operators to choose between partial spread or full circular distribution.

Durable Bearings & Protected Joints

Heavy-duty bearings and shielded moving joints prevent dust/mud entry and ensure long service life, even in high-dust environments like grain yards.

Adjustable Discharge Height

Allows compatibility with trolleys/trucks of varying heights and supports efficient gravity-based flow.

Easy Transport & Setup

Designed with foldable components and a balanced footprint, allowing the machine to be moved easily across yards and mounted quickly onto tractors.

Low Fuel & Labour Requirement

Optimized for efficient PTO operation, reducing tractor load and fuel consumption. Minimal manual handling is needed, significantly lowering labour dependency.

Model Summary

The Bull Radial Unloader is optimized for 40–55 HP tractors, making it suitable for a wide range of mid-sized tractors commonly used across Indian farms, warehouse operations, and grain markets. Its high-efficiency radial discharge arm allows wide-area material distribution, enabling rapid unloading in significantly reduced time.

The machine’s robust design, precise rotational components, adjustable discharge settings, and reliable PTO-driven operation ensure exceptional durability and consistent performance. Whether used for unloading grain trucks during peak season procurement or for daily warehouse operations, the Bull Radial Unloader delivers uniform distribution, low maintenance, and efficient material management.

Detailed Specifications of Bull Radial Unloader

Here is a detailed summary of the technical specifications of the Bull Radial Unloader. These specifications may vary slightly across sub-models, but the following represent the standard Bull Agro configuration:

Parameter — Specification Table

|

Parameter

|

Specification

|

|

Suitable Tractor HP

|

40 – 55 HP

|

|

Drive Type / Power Source

|

PTO-driven (540 RPM)

|

|

Rotation Angle

|

180° to 360° (depending on variant)

|

|

Discharge Capacity

|

High-capacity radial spread (varies with moisture and crop type)

|

|

Unloading Mechanism

|

Radial arm with controlled flow outlet

|

|

Discharge Height Adjustment

|

Adjustable height to suit multiple trolley levels

|

|

Rotor Type

|

Balanced heavy-duty rotor for smooth material flow

|

|

Material Compatibility

|

Grains, pulses, oilseeds, granular fertilizers, fine loose materials

|

|

Frame Construction

|

High-tensile steel with reinforced joints

|

|

Bearing Type

|

Heavy-duty sealed bearings for dust & moisture protection

|

|

PTO Shaft

|

Standard PTO with protective cover

|

|

Machine Weight

|

Approx. 315–390 kg (varies by sub-model)

|

|

Support Structure

|

Sturdy base frame with stability-enhancing supports

|

|

Operational Controls

|

Manual/assisted rotation control (model-dependent)

|

|

Protection Features

|

Shielded joints, covered bearings, PTO guard

|

|

Mobility Features

|

Balanced design for easy mounting, movement & positioning

|

|

Additional Design Features

|

Foldable/compact arm design, vibration-reduction mounting, heavy-grade outlet chute

|

|

Included Accessories

|

PTO shaft, operational toolkit, safety guard components

|

These specifications make the Bull Radial Unloader an exceptionally effective bulk-handling and unloading solution — built for speed, durability, efficiency, and operator convenience.

Bull Radial Unloader – Price in India

As per recent listings and trusted dealers, the Bull Radial Unloader typically falls within the price range of ₹4,00,000 to ₹4,50,000, depending on the model variant, optional features, and transportation costs.

Considering its efficiency in bulk material unloading, labour savings, reduced operational time, and durable construction, this price range offers a strong cost-to-benefit advantage for medium- to large-scale grain handling operations, warehouses, and commercial farms.

Why Choose Tractor For Everyone for the Bull Radial Unloader?

At Tractor For Everyone, we make it simpler for farmers and operators to find the right mechanized farm equipment and material-handling solutions with complete confidence. Our dedicated section for the Bull Radial Unloader provides:

Detailed specifications and feature breakdown in one place.

Accurate price information, dealer contacts, and availability status.

Smart tools like tractor HP filters, comparison options, and operational guidance for easy selection.

Transparent, verified listings that ensure genuine product information and peace of mind during purchase.

Whether you operate a small storage yard or a large procurement center, our platform helps you choose the best radial unloader suitable for your tractor, field, or yard setup, without wasting time or effort.

Popular Bull Radial Unloader Models

Here are some of the widely used Bull Radial Unloader models, preferred by Indian farmers, warehouse operators, and commercial bulk-handling units:

|

Model Name

|

Key Features

|

Suitable For / Best Use

|

|

Bull Radial Unloader 180°

|

Single radial arm, controlled flow, 180° spread, 40–50 HP tractors

|

Medium-scale grain handling, unloading from trolleys, warehouse use

|

|

Bull Radial Unloader 240°

|

Larger radial arm, extended coverage, vibration-reduction system, 45–55 HP tractors

|

Larger farms and commercial warehouses needing wider material spread

|

|

Bull Radial Unloader 360°

|

Full circular rotation, heavy-duty rotor, high-capacity discharge, 50–55 HP tractors

|

High-volume bulk unloading, cooperative societies, grain procurement centers

|

|

Bull Radial Unloader Mini

|

Compact design, lightweight frame, 180°–200° spread, 35–45 HP tractors

|

Small storage yards, limited space, low-volume grain handling

|

|

Bull Radial Unloader Multi-Crop

|

Adjustable rotor speed, moderate to high discharge rate, adaptable to grains, pulses, fertilizers

|

Farms or warehouses handling multiple types of loose materials

|

Note: Model names, features, and availability may vary based on dealer stock, regional demand, and season. Always verify tractor HP compatibility, radial rotation range, and discharge capacity before purchase.

Benefits – What Makes Bull Radial Unloader Stand Out

The Bull Radial Unloader’s signature radial arm and controlled flow outlet allow bulk materials — such as grains, pulses, oilseeds, and granular fertilizers — to be unloaded quickly and evenly across a large area. Unlike manual shovelling or linear conveyor systems, the radial spread ensures uniform coverage, reducing the need for additional labour to level or redistribute material.

For commercial farms, procurement centers, and warehouses, this results in consistent stacking, faster unloading, and reduced downtime.

Manual unloading of bulk materials is time-consuming and labour-intensive, especially for medium to large storage yards or grain procurement operations. Mechanizing the process with the Bull Radial Unloader:

For farms handling multiple trolleys or trucks daily, these savings translate to hours of labour and operational efficiency gains.

Designed for 40–55 HP tractors, the Bull Radial Unloader is compatible with most mid-range tractors prevalent in India. Its standard PTO shaft and optional hydraulic-assisted rotation provide seamless integration, making it easy to attach, operate, and maintain across various setups.

The machine is built to endure heavy-duty operations:

-

High-Efficiency Material Unloading

-

Significant Time, Labour, and Fuel Savings

-

Reduces manual shovelling by 70–80%.

-

Cuts tractor idle time due to faster unloading cycles.

-

Lowers fuel consumption due to optimized PTO operation and lightweight rotor design.

-

Compatibility with Common Tractors & Power Sources

-

Durability and Low Maintenance

- Heavy-gauge steel frame with reinforced joints

- Sealed heavy-duty bearings resistant to dust and moisture

- Protected PTO shaft and rotor assemblies

- Vibration-reduction mounting for smooth operation

-

Additionally, lubrication points and accessible bearings allow for quick routine maintenance, extending machine life and ensuring reliable performance in high-throughput scenarios.

While primarily designed for grains, the radial unloader can handle:

-

Versatility – Beyond Grains

- Pulses, oilseeds, and seeds

- Granular fertilizers and feed

- Other loose, dry, or free-flowing materials

This versatility makes it a smart investment for multi-crop farms, warehouses, and bulk-handling contractors.

Use Cases – Who Should Use Bull Radial Unloader

The Bull Radial Unloader is ideal for:

- Medium to large farms that handle bulk grain harvests and require quick, even distribution.

- Commercial storage yards and warehouses needing fast unloading from trucks or trolleys.

- Grain procurement centers and cooperative societies where efficiency and minimal labour are critical.

- Agricultural contractors or service providers managing multiple farms or warehouses — the radial design allows coverage over large areas with minimal repositioning.

- Multi-crop operations where different loose materials need safe, even, and efficient unloading.

Its combination of speed, coverage, and operator convenience ensures that large-scale operations can maintain productivity and reduce reliance on seasonal or temporary labour.

Operating Considerations & Best Practices

To get the best performance and longevity from your Bull Radial Unloader, and to ensure safe, efficient operation, the following practices are recommended:

Tractor Compatibility

Ensure your tractor falls within the 40–55 HP range as per the specifications. Using a lower HP tractor may result in slower rotation, incomplete unloading, or stress on the PTO. Overpowered tractors are acceptable, but may require adjusting rotational speed for optimal discharge.

PTO Setup & Connection

Connect the unloader using the 3-point linkage and standard PTO shaft. Always ensure the PTO guard is intact, and that the shaft is securely coupled to avoid vibration or accidental disengagement during operation.

Field/Yard Preparation

For optimal performance:

- Level the unloading area to prevent spillage or uneven distribution.

- Avoid excessively wet or sticky materials that may clog the rotor or radial arm.

- Maintain at least open space equal to the maximum radial spread to ensure full coverage.

Blade & Rotor Maintenance

Though the Bull Radial Unloader uses a heavy-duty rotor, frequent inspection is necessary:

- Check for wear or damage, especially if handling abrasive grains or fertilizers.

- Ensure bearings and joints are lubricated at regular intervals.

-

Operator Safety

- Never operate the PTO without the protective cover.

- Keep bystanders and animals clear of the operational radius.

- Always turn off the tractor before performing maintenance or adjustments.

-

Storage

- Use the stable frame or parking stand when not in use.

- Store in a dry, covered location to prevent corrosion on the rotor and frame.

Comparing Bull Radial Unloader with Other Unloaders & Alternative Methods

When selecting a material handling solution, it is useful to compare the Bull Radial Unloader with other options:

Radial Unloader vs Manual Unloading

- Manual shovelling is labour-intensive, slower, and inconsistent in coverage.

- The Bull Radial Unloader distributes material evenly with minimal labour, reducing operator fatigue and speeding up unloading cycles.

Radial Unloader vs Linear Conveyor Unloader

Bull Radial Unloader Real-World Benefits: What Operators Gain

Based on typical usage across farms, warehouses, and procurement centers, the Bull Radial Unloader provides the following advantages:

- Significant Time Savings

Bulk unloading that would normally require hours of manual labour can be completed in minutes, especially when handling multiple trolleys or trucks. This is critical during peak harvest seasons or busy procurement periods.

- Reduced Labour Dependency

Manual handling and shovelling are largely eliminated. One operator with a tractor can handle what previously required multiple workers, reducing both costs and logistical challenges.

- Improved Material Distribution

The radial mechanism ensures uniform, controlled discharge, minimizing spillage, wastage, and uneven stacking — which is particularly important for storage optimization and preventing post-harvest losses.

- Durability and Long Service Life

With high-tensile steel construction, reinforced joints, and sealed bearings, the machine withstands continuous operation in demanding conditions. Operators report consistent performance even in high-volume, repetitive unloading tasks.

- Flexibility Across Materials

Though optimized for grains, the Bull Radial Unloader also handles pulses, oilseeds, fertilizers, and other free-flowing materials, making it a versatile investment for multi-purpose operations.

- Enhanced Farm/Warehouse Management

By reducing unloading time and labour requirements, operators can better manage scheduling, maintain quick turnaround of trolleys or trucks, and optimize storage space efficiently.

Bull Radial Unloader Potential Limitations & Things to Watch Out For

While the Bull Radial Unloader is highly effective, operators should be aware of potential limitations:

Tractor HP Limitation

The machine is designed for 40–55 HP tractors. Using a tractor below this range may reduce rotation speed and unloading efficiency, while a much higher HP tractor may require adjusting the rotational mechanism for optimal results.

Material Moisture & Stickiness

Very wet, sticky, or clumped materials may clog the rotor or discharge chute, reducing efficiency and requiring manual intervention or pre-drying.

Space Requirements

To achieve full radial coverage, the area around the unloader must be sufficient. Operating in confined spaces may reduce the effective spread radius.

Maintenance Necessity

Regular inspection of bearings, PTO shaft, rotor, and joints is essential. Ignoring maintenance can lead to wear, uneven rotation, and costly repairs.

Initial Investment

For very small storage yards or sub-acre farms, the initial cost may seem high relative to the volume of material handled. ROI improves with medium to large-scale operations.

Operator Skill & Safety

Skilled handling is recommended to maximize efficiency. Improper PTO use, incorrect linkage attachment, or unsafe rotation practices can cause accidents or damage to the implement.

Guidance: Is the Bull Radial Unloader Right for Your Operation?

If your operations meet the following criteria, the Bull Radial Unloader is an ideal investment:

- You have or plan to use a 40–55 HP tractor.

- You handle medium to large-scale bulk material operations, such as multiple trolleys, trucks, or warehouse storage units.

- You aim to reduce manual labour, save time, and improve material distribution efficiency.

- You operate in yards or fields with enough open space for radial discharge.

- You are prepared to maintain bearings, PTO components, and rotor assemblies to ensure long-term performance.

- You may handle multiple types of loose materials, not just grains, maximizing the implement’s versatility.

-

Conversely, if your operation is very small (<1 acre or minimal storage), uses low HP tractors, or handles extremely wet or sticky materials, smaller or alternative unloading solutions may be more practical. You may also consider combining mechanical unloading with manual methods for very constrained spaces.

Practical Tips for On-Field or On-Site Use

To get optimal results and longevity from your Bull Radial Unloader:

Pre-Operation Checks

- Inspect PTO connection, 3-point linkage, and safety guards.

- Ensure the rotor, bearings, and radial arm are free of debris.

-

Field/Yard Preparation

- Level the unloading area.

- Remove obstacles or moisture-clogged patches that could interfere with smooth rotation.

-

Operational Tips

- Adjust the rotation angle according to yard size and material type.

- Operate at moderate PTO speed to prevent overloading the rotor.

- Avoid abrupt starts/stops to minimize vibration and mechanical stress.

-

Maintenance

- Clean rotor, bearings, and joints after each use, especially if materials are dusty or moist.

- Lubricate bearings and PTO shaft at recommended intervals.

- Inspect for wear or damage to rotor arms and discharge chute.

-

Safety

- Never leave the machine unattended while the PTO is engaged.

- Keep bystanders and animals outside the operational radius.

- Always switch off the tractor before adjustments or maintenance.

-

Storage

- Use the stable frame or parking stand.

- Store in a dry, covered location to prevent rust and corrosion.

Conclusion: Overall Value & Recommendation

The Bull Radial Unloader is a highly durable, operator-friendly, and efficient bulk unloading implement. Its radial arm design, controlled flow mechanism, and robust construction make it ideal for medium to large-scale farms, warehouses, and grain handling operations.

For operators using 40–55 HP tractors, the machine provides:

- Labour savings by reducing manual shovelling.

- Time efficiency, enabling faster unloading of trolleys and trucks.

- Uniform material distribution, preventing spillage and improving stacking.

- Versatility, as it handles multiple bulk materials beyond just grains.

- Low operational and maintenance costs, with simple PTO-driven operation and durable components.

-

When used with proper maintenance and operator care, the Bull Radial Unloader delivers long-term reliability, consistent performance, and a strong return on investment — making it a smart addition for modern, mechanized bulk handling operations.

.jpg)

✔ Pros

✔ Pros  ✘ Cons

✘ Cons