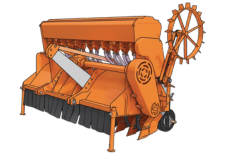

The Hind 399 is purpose-built to tackle the challenges faced by small to medium-scale farmers in India. Its design merges multiple harvesting operations into one machine, eliminating traditional inefficiencies such as manual cutting, separate threshing, and cleaning processes. By combining these functions, the Hind 399 ensures higher throughput, reduced operational delays, and minimized grain loss, which is especially critical for crops like paddy, where timely harvesting directly affects yield quality.

Key Features

- Compact self-propelled chassis: Ideal for farms with narrow or irregular plots, allowing easy movement between rows and across uneven terrain.

- 60–76 HP diesel engine: Offers the right balance of power and fuel efficiency to operate the cutter, threshing drum, straw walkers, and cleaning systems simultaneously.

- Large fuel tank (180 L): Minimizes refueling interruptions during long harvesting sessions, improving operational continuity and productivity.

- Wide cutter bar (~2744 mm): Increases field coverage, reducing harvesting time for medium-scale farms.

- Dual threshing drums: Enables farmers to switch between wheat and paddy modes, supporting multi-crop operations without requiring additional attachments.

- Retractable finger auger and crop dividers: Reduce header blockage, allowing smoother crop flow and minimizing downtime during harvest.

- Ergonomic operator seat and controls: Designed for comfort and ease of operation during extended field hours.

- Hydraulic steering: Provides smooth directional control and minimizes operator fatigue.

- Easy-access maintenance points: Simplify cleaning, servicing, and minor repairs, ensuring consistent performance throughout the harvest season.

- Durable frame and rust-resistant coating: Ensures longevity and reliable operation across diverse field and weather conditions.

Model Summary

The Hind 399 is optimized for small to medium-sized farms where mechanization is needed but large combines are not economically viable. Its engine power, field coverage, and ergonomic design allow farmers to complete harvests faster, with reduced labor dependency and minimal grain loss. The machine’s multi-crop capability and durable construction ensure long-term utility and investment protection, making it a practical choice for farmers aiming to modernize their operations without overextending resources.

Detailed Specifications of Hind 399 Combine Harvester

|

Parameter

|

Specification

|

|

Model Name

|

Hind 399 Small Combine Harvester

|

|

Type

|

Compact self-propelled combine

|

|

Engine Power

|

60–76 HP

|

|

Fuel Tank Capacity

|

180 L

|

|

Electrical System

|

18 V

|

|

Battery

|

12 V, 100 AH

|

|

Effective Cutter Bar Width

|

2744 mm

|

|

Knife Stroke

|

75 mm

|

|

Knife Speed

|

~1.2 m/s @ 1700 rpm

|

|

Strokes per Minute

|

976

|

|

Threshing Drum

|

Wheat (Rasp Bar) / Paddy (Peg Tooth)

|

|

Threshing Width

|

Wheat ~1210 mm / Paddy ~1205 mm

|

|

Threshing Drum Dia

|

Wheat ~574 mm / Paddy ~428 mm

|

|

Concave Width

|

Overall 1285 mm / Effective 1260 mm

|

|

Concave Types

|

Open flat bars / Flat bars with pegs

|

|

Straw Walkers

|

4 Nos. – closed rack type

|

|

Grain Tank Capacity

|

~8500 kg

|

|

Tyres

|

Front 14.4 × 28 / Rear 7.50 × 16

|

|

Machine Weight

|

~5500 kg

|

|

Operator Controls

|

Ergonomic & easy-reach

|

|

Additional Features

|

Robust steel frame, hydraulic steering, easy service access, rust-resistant coating

|

Hind 399 Combine Harvester – Price in India

The Hind 399 falls into the affordable mini/compact combine segment, making mechanization accessible for small to medium farms. With prices ranging from ₹19 Lakh to ₹26 Lakh, it provides a strong value proposition by enabling faster harvest, labor savings, and improved grain quality. The machine’s cost is balanced by its long-term durability, fuel efficiency, and low operational downtime, making it an investment that can yield returns over multiple cropping seasons.

Why Choose Hind 399 Combine Harvester?

The Hind 399 is designed to enhance operational efficiency and reduce labor dependency, addressing common challenges faced by Indian farmers. Its compact, self-propelled design ensures maneuverability in fields with limited space, while the engine and cutter-bar configuration maximize productivity for multiple crops. By providing an all-in-one solution for cutting, threshing, and cleaning, the Hind 399 minimizes manual labor and reduces grain losses, offering both economic and practical advantages. Its maintenance-friendly design and ergonomic controls make it accessible even for operators with limited mechanized farming experience.

Popular Hind Combine Harvester Models

|

Model Name

|

Key Features

|

Suitable For

|

|

Hind 399

|

60–76 HP, compact, self-propelled, ~2744 mm cutter bar

|

Small to medium farms; paddy, wheat, soybean, maize

|

|

Hind 799

|

~4280 mm cutter bar, 6 straw walkers, larger grain tank

|

Medium to larger farms, faster coverage

|

|

Hind 999

|

4.2–4.4 m cutting width, 101 HP

|

Large fields, contractors

|

|

Hind 999 Dx

|

101 HP, wide cutter bar, advanced cleaning

|

High-efficiency multi-crop harvesting

|

Benefits – What Makes Hind 399 Combine Harvester Stand Out

- All-in-One Harvesting Efficiency:

The Hind 399 performs cutting, threshing, separation, cleaning, and grain collection in a single pass. Traditional manual harvesting or tractor-mounted reapers require multiple steps, increasing labor, time, and grain losses. With the Hind 399, farmers can achieve uniform results and minimize the risk of crop damage.

- Time, Labor, and Fuel Savings:

On a 10-acre wheat field, manual harvesting can take several days with a team of 5–10 workers. Using the Hind 399, the same field can be harvested in less than a day with one operator, reducing labor costs and enabling timely harvest. Fuel-efficient engine design ensures that cost per acre remains low, even for medium-sized farms.

- Multi-Crop Flexibility:

The dual threshing drums allow switching between wheat and paddy, while minor adjustments enable maize and soybean harvesting. This versatility reduces the need for separate machines for each crop, providing a single, cost-effective solution for farmers practicing crop rotation or intercropping.

- Reduced Grain Loss:

Efficient straw walkers and proper drum adjustments minimize the escape of grains during threshing. Farmers benefit from higher effective yields, translating directly into increased revenue.

- Operator Comfort and Safety:

Ergonomic seating, intuitive controls, hydraulic steering, and clear visibility of the cutter and threshing systems reduce operator fatigue. Safety features such as protective guards on moving parts minimize the risk of accidents.

- Durable, Long-Term Investment:

Robust steel frame construction, rust-resistant coating, and high-quality components ensure that the Hind 399 withstands repeated use over multiple cropping seasons, reducing replacement costs and providing a good return on investment.

- Field Adaptability:

Its compact design allows the combine to operate effectively in narrow or uneven fields, while the adjustable cutter bar and drums can be tuned for specific crop and field conditions.

- Improved Harvest Scheduling:

Faster and more predictable harvests allow farmers to better schedule post-harvest operations, such as storage, marketing, or land preparation for the next crop.

Use Cases – Who Should Use Hind 399

- Small to Medium Farms (5–50 acres):

Farmers managing multiple plots or fields benefit from its compact size and operational efficiency.

- Multi-Crop Farms:

Farms growing wheat, paddy, maize, or soybean can utilize the dual threshing drum system to harvest multiple crops with minimal adjustments.

- Contract Harvesting Providers:

Agricultural service providers can harvest multiple small farms efficiently due to the combine’s self-propelled design and relatively large cutter width.

- Operators Seeking Mechanization:

Farmers transitioning from manual harvesting or tractor-mounted reapers will find the Hind 399 easier to use and more productive, allowing them to scale operations without increasing labor requirements.

- Farmers in Fragmented Landscapes:

Plots with narrow rows, irregular shapes, or uneven terrain can be harvested effectively due to the machine’s compact dimensions and agile steering.

Operating Considerations & Best Practices

- Pre-Operation Checks:

Inspect the cutter bar, threshing drums, straw walkers, and hydraulic systems. Ensure the engine oil, diesel, and lubrication points are sufficient before starting.

- Field Conditions:

Avoid excessively wet, waterlogged, or rocky fields. While the combine can handle typical paddy or wheat conditions, very heavy or saturated soil may reduce efficiency. Drainage before operation is recommended.

- Engine Warm-Up:

Allow the diesel engine to reach operating temperature before engaging the cutter bar and threshing systems.

- Adjusting Cutter and Threshing Drums:

For wheat, set the rasp bar drum clearance to ensure thorough threshing without grain damage. For paddy, adjust the peg tooth drum and concave to accommodate wet, soft grains.

- Grain Tank Management:

Monitor tank levels and unload at appropriate intervals to avoid overflow, which can disrupt operations or damage grain.

- Maintenance Routine:

Clean debris from cutter, drums, straw walkers, and augers. Grease moving parts and check belts, bearings, and hydraulic components regularly.

- Operator Safety:

Use all protective guards, avoid working near people or animals, and ensure the PTO and hydraulic connections are secure. Always switch off the engine before performing maintenance.

- Storage:

Store the combine in a dry, covered area after harvest. Apply rust-preventive coatings and remove moisture to prevent corrosion.

Comparing Hind 399 with Other Harvest Methods

Combine vs Manual Harvesting:

Manual harvesting is labor-intensive, slow, and prone to grain loss. The Hind 399 combines cutting, threshing, cleaning, and grain collection in one pass, significantly reducing labor costs and minimizing post-harvest losses.

Combine vs Tractor-Mounted Reapers:

Tractor-mounted reapers are faster than manual harvesting but require separate threshing and cleaning. The Hind 399 integrates all operations, saving time and fuel while producing cleaner grain.

Hind 399 vs Larger Combines:

Larger combines cover more area but are expensive and less maneuverable. For small to medium plots, the Hind 399 offers an optimal balance between affordability, coverage, and operational efficiency.

Multi-Crop Advantage:

Few compact combines offer dual threshing drums for both wheat and paddy. The Hind 399 allows farmers to switch between crops efficiently, increasing the machine’s utility and return on investment.

Real-World Benefits

- Significant reduction in harvest time: A 10-acre wheat field can be harvested in a single day versus several days manually.

- Labor cost reduction: Less reliance on seasonal labor reduces overall operational expenses.

- Higher effective yields: Efficient separation and minimal grain loss improve harvest quality.

- Fuel and operational cost efficiency: Optimized engine and hydraulic systems reduce per-acre fuel consumption.

- Versatile usage: Suitable for wheat, paddy, maize, soybean, and minor adjustments for other grains.

- Improved scheduling: Faster harvest allows timely land preparation and planting for subsequent crops.

Potential Limitations

- Requires trained operators for optimal use.

- High upfront cost may not suit very small farms (<5 acres).

- Best suited for small to medium farms; not ideal for extremely fragmented plots.

- Regular maintenance needed to maintain efficiency.

- Extreme waterlogged or rocky fields can reduce performance.

Guidance: Is Hind 399 Right for Your Farm?

Consider Hind 399 if:

- You manage small to medium farms with significant grain acreage.

- You want to mechanize harvest operations.

- You grow wheat, paddy, maize, or soybean.

- You need a self-propelled, easy-to-operate combine.

Smaller farms (<5 acres) or very fragmented plots may consider smaller harvesters or combine services.

Practical Tips for On-Field Use

- Inspect all moving parts before use.

- Drain excessively wet fields for better efficiency.

- Make preliminary shallow passes in compact soil before full harvesting.

- Adjust drum clearance according to crop type.

- Clean and lubricate moving parts regularly.

- Avoid working on steep slopes to prevent tipping.

- Store in a sheltered, dry location after use.

Conclusion: Overall Value & Recommendation

The Hind 399 Combine Harvester is a compact, versatile, and durable solution for small to medium farms. It significantly reduces labor requirements, improves grain quality, saves time, and provides a long-term investment for multi-crop operations. With proper maintenance, operator training, and thoughtful field management, the Hind 399 can transform harvest efficiency, particularly in farms growing wheat, paddy, maize, or soybean.

✔ Pros

✔ Pros  ✘ Cons

✘ Cons